How Weather Affects Commercial Drywall Installation

Weather conditions impede numerous construction projects, and commercial drywall work is no exception. Extreme temperatures, high humidity, and precipitation hinder the installation process.

Construction managers who plan around weather patterns complete projects on schedule more consistently. They also avoid the expensive rework that comes from installing drywall under poor conditions. Professional contractors must comprehend how weather affects commercial drywall installation in order to conduct a successful project without delays.

Smart scheduling considers both current conditions and upcoming forecasts to minimize weather-related complications.

Temperature’s Impact on Drywall Materials

Cold Temperatures

Cold temperatures create multiple challenges for drywall installation teams. Joint compound becomes thicker and harder to spread when temperatures drop below 50 degrees Fahrenheit. The material may not bond correctly to surfaces, leading to cracks and separation as the building settles.

Extreme cold can cause drywall sheets to become brittle. Sheets that normally bend slightly during installation may crack or break when handled in freezing conditions. Workers also face reduced dexterity in cold weather, making precise installation more difficult.

Hot Temperatures

Hot temperatures present different problems. Installation professionals might find it difficult to achieve smooth finishes because the joint compound dries too quickly.

Temperatures above 90 degrees Fahrenheit can cause the compound to crack as it dries unevenly. This obstacle prevents workers from having adequate time to sand and blend seams properly.

Humidity Control During Installation

High humidity significantly extends drying times for joint compound and tape. When relative humidity exceeds 70 percent, the compound may take twice as long to dry completely. This delay pushes back subsequent coats and finishing work.

Low humidity creates the opposite problem. The joint compound dries too quickly in arid conditions before installers can produce smooth finishes. The rapid moisture loss can cause shrinkage cracks that require additional repair work.

Professional teams monitor humidity levels throughout the installation process. They use dehumidifiers in high-moisture conditions and humidifiers when the air becomes too dry. Maintaining humidity between 40 and 60 percent provides ideal working conditions for most drywall applications.

Precipitation and Moisture Challenges

Rain poses obvious threats to drywall materials and installation quality. Direct water exposure can damage drywall sheets, causing them to soften and lose structural integrity. Even minor leaks can create problems that aren’t immediately visible.

Snow presents similar moisture risks plus additional handling difficulties. Workers must clear snow from work areas and materials before beginning installation. Melting snow can create puddles that increase humidity levels in enclosed spaces.

Moisture from precipitation can also affect the building structure itself. Wet framing members may warp or shift, making drywall installation more challenging. Metal studs can develop rust when exposed to moisture, potentially staining finished drywall surfaces.

Seasonal Installation Considerations

Winter installations require careful planning and preparation. Heating systems must maintain consistent temperatures throughout the work area. Contractors use temporary heating equipment to create suitable conditions for joint compound application and drying.

Spring weather brings variable conditions that can change rapidly. Temperature swings between day and night affect curing times and material performance. Rain becomes more frequent, requiring flexible scheduling and waterproofing measures.

Summer heat demands different strategies. Early morning and evening work schedules help avoid peak temperatures. Adequate ventilation becomes important for both material performance and worker comfort. Air conditioning may be necessary to maintain suitable working conditions.

Fall offers some of the most favorable conditions for drywall work. Temperatures remain moderate, and humidity levels tend to be more stable. However, short daylight hours can limit working time for projects without adequate artificial lighting.

Weather-Related Quality Issues

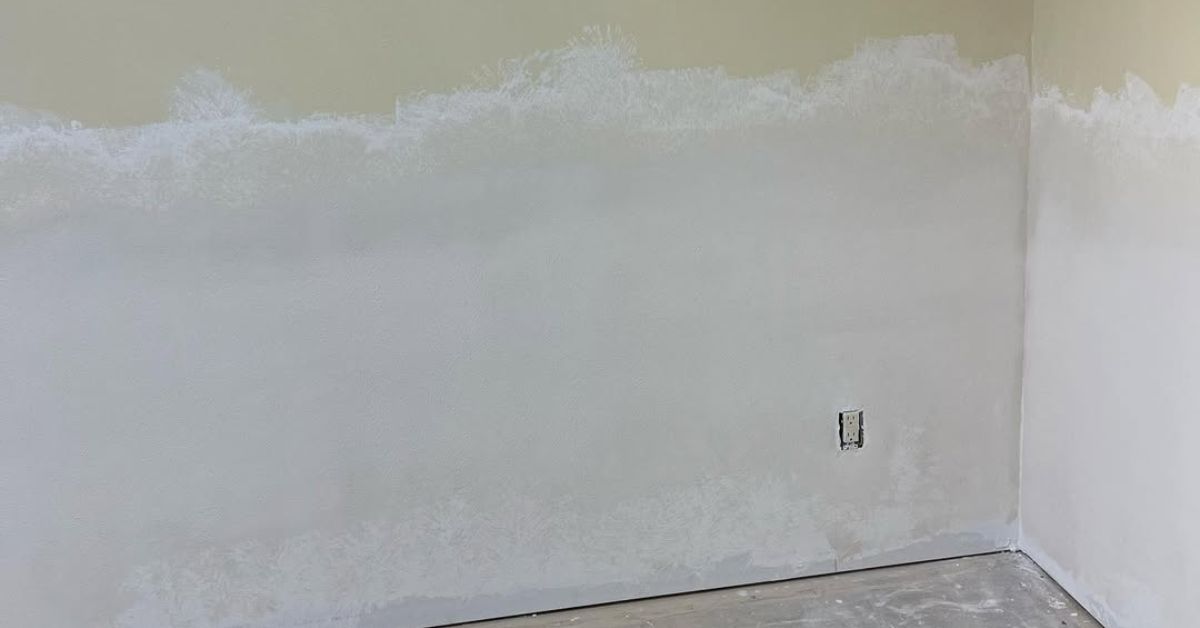

Poor weather conditions during installation cause lasting quality problems. Applying the joint compound in inadequate conditions may crack, shrink, or fail to adhere correctly. These issues are typically undetectable until weeks or months after completion.

Uneven Drying

Uneven drying caused by temperature or humidity variations creates visible seams in finished walls. The compound may dry at different rates across a single sheet, leading to wavy or bumpy surfaces that require extensive rework.

Moisture Intrusion

Moisture intrusion during installation can cause mold growth behind finished walls. This problem may not become evident until occupants notice odors or health issues. Prevention requires careful moisture control throughout the installation process.

Best Practices for Weather Management

Successful contractors develop comprehensive weather management strategies. They monitor forecasts closely and adjust schedules when conditions become unsuitable. Backup plans help maintain progress when unexpected weather changes occur.

Material storage requires weather protection at all times. Drywall sheets and joint compound must remain dry before, during, and after installation. Covered storage areas and ample ventilation maintain material quality.

Key weather management practices include:

- Monitoring temperature and humidity levels continuously.

- Using temporary climate control equipment when necessary.

- Scheduling work during favorable weather windows.

- Protecting materials from moisture exposure.

- Training crews to recognize weather-related problems.

- Having contingency plans for unexpected weather changes.

Planning Around Weather Forecasts

Professional project managers integrate weather forecasting into their scheduling processes. They identify weather-sensitive phases of drywall installation and plan them during predicted favorable conditions. Extended forecasts help with longer-term planning decisions.

Short-term adjustments become necessary when forecasts change. Teams may need to accelerate certain phases before the weather deteriorates or delay work until conditions improve. Flexibility in scheduling helps maintain overall project timelines.

Communication between weather monitoring and field crews prevents costly mistakes. Site supervisors receive regular weather updates and can make real-time decisions about continuing or suspending work. Clear protocols help teams respond quickly to changing conditions.

Choose Professional Drywall Installation Solutions

Temperature fluctuations impact how drywall materials behave during installation and curing. Humidity levels determine how quickly joint compound dries and whether it adheres correctly. Rain and snow create obvious obstacles, but even seemingly minor weather changes can affect material performance and worker safety.

To overcome weather challenges in drywall installation , professional expertise and proper planning are necessary. Experienced contractors understand how environmental conditions impact material performance and adjust their methods accordingly. They invest in climate control equipment and weather monitoring tools that help maintain consistent quality.

Professional commercial drywall installation teams like Rival Drywall have the experience and resources to handle weather-related challenges effectively. We know how to handle various environmental factors and deliver high-quality results. Contact Rival Drywall today to discuss your next commercial project and learn how professional planning can overcome weather-related obstacles.